Structural members that are made up of two or more different materials are known as composite elements. The main benefit of composite elements is that the properties of each material can be combined to form a single unit that performs better overall than its separate constituent parts. The most common form of composite element in construction is a steel-concrete composite, however, other types of composites include; steel-timber, timber-concrete, plastic-concrete, and so on.

As a material, concrete works well in compression, but it has less resistance in tension. Steel, however, is very strong in tension, even when used only in relatively small amounts. Steel-concrete composite elements use concrete’s compressive strength alongside steel’s resistance to tension, and when tied together this results in a highly efficient and lightweight unit that is commonly used for structures such as multi-story buildings and bridges.

Composite slabs

Composite slabs are typically constructed from reinforced concrete cast on top of profiled steel decking, (re-entrant or trapezoidal).

The decking is capable of acting as formwork and a working platform during the construction stage, as well as acting as external reinforcement at the composite stage. Decking is lifted into place in bundles and distributed across the floor area by hand.

Slab depths range from 130 mm upwards. Slabs are most commonly made of concrete because of their mass and stiffness which can be used to reduce the floor’s deflections and vibrations, and achieve the necessary fire protection and thermal storage. Steel is often used as the supporting system underneath the slab due to its superior strength-weight and stiffness-weight ratio and ease of handling.

Re-entrant or trapezoidal decking is usually 50-60 mm deep and can span around 3 m unsupported. Trapezoidal profiles of 80 mm deep can span around 4.5 m unsupported. Deep decking is trapezoidal decking that is over 200 mm deep, and if required, additional reinforcement may be placed in the decking troughs. Deep decking can span around 6 m unsupported.

Galvanized steel is used for the decking and is usually around 1 mm thick. To avoid local buckling, stiffeners may be used to stiffen the upper flange and support hangers for relatively lightweight items to be suspended from the soffit. Dimples known as embossments are rolled onto the decking profile which traps the concrete around the re-entrant parts of the profile and allows for interlocking.

Where openings are required in composite slabs these are best formed at the construction stage as opposed to having to cut out sections of concrete. Up to 300 sq. mm openings do not need additional provisions, but up to 700 sq. mm require additional local reinforcement around the opening. If openings are in excess of 700 sq. mm, trimming steel can be used as support.

Composite beams

A downstand beam is connected to a composite slab by the use of through-deck welded shear studs. Alternatively, a precast concrete slab sits on top of the steel beam’s top flange. The effective span range is around 6-12 m. Other variations on downstand beams can reach spans of 20 m or more.

Shallow floors

Shallow floors are where the main part of the steel section is within the concrete slab depth and can be used for a span range of around 4-9 m. As opposed to downstand beams, the slab sits on the upper surface of the bottom flange instead of the upper surface of the top flange, with a key consideration being the torsion that is applied to the beam. The slab may be either in situ concrete on deep steel decking, usually around 225 mm, or precast concrete.

The benefits of shallow floors are that since the slabs and beams are placed within the same zone, there are none of the interruptions found with downstand beams, and there is often no need for additional fire protection.

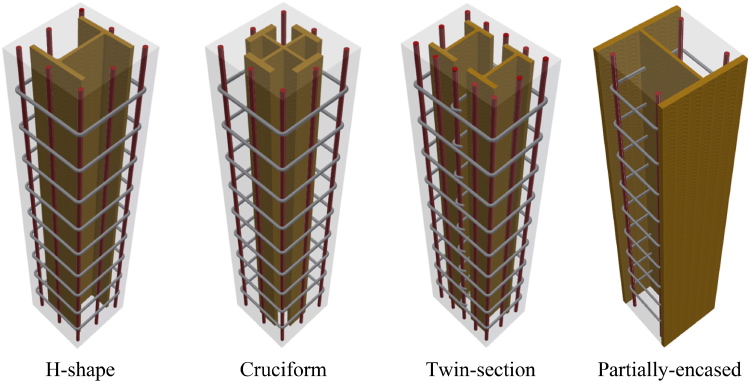

Composite columns

Composite columns can have high strength for a relatively small cross-sectional area, meaning that useable floor space can be maximized. There are several different types of composite columns; the most common being a hollow section steel tube that is filled with concrete, or an open steel section encased in concrete. The concrete infill adds to the compression resistance of the steel section, preventing the steel from buckling. Its fire-resistant properties can permit the column to be left unprotected or only lightly protected.

Rectangular and circular hollow sections are most commonly used, although rectangular sections are beneficial for having flat faces suitable for end plate beam-to-column connections. However, fin plates can be used for rectangular and circular shapes.

No comment